Technologische Möglichkeiten:

- Gas plasma cutting machine CNC HD 260, table: 3000 mm x 12000 mm, sheets: 3 mm-250 mm

- CNC drilling and cutting line for processing profiles

- SNC drilling machine for gusset plates

- Press up to 200 tons

- Rolling sheet metal up to 25 mm, width 2500 mm

- Boring mills, drilling machines, lathes, milling machines, grinding machines, bending machines

- Bandsaw up to 640 mm

- Overhead traveling crane up to 26 tons

- Continuous blast machine 1600/600 mm

- Blasting cabin 12 m / 5 m / 5 m

- Painting line 9 m / 5 m / 5 m

- Welding MIG / MAG, TIG, electrode

- Electrostatic coating, AIR-LESS technology

- Montage

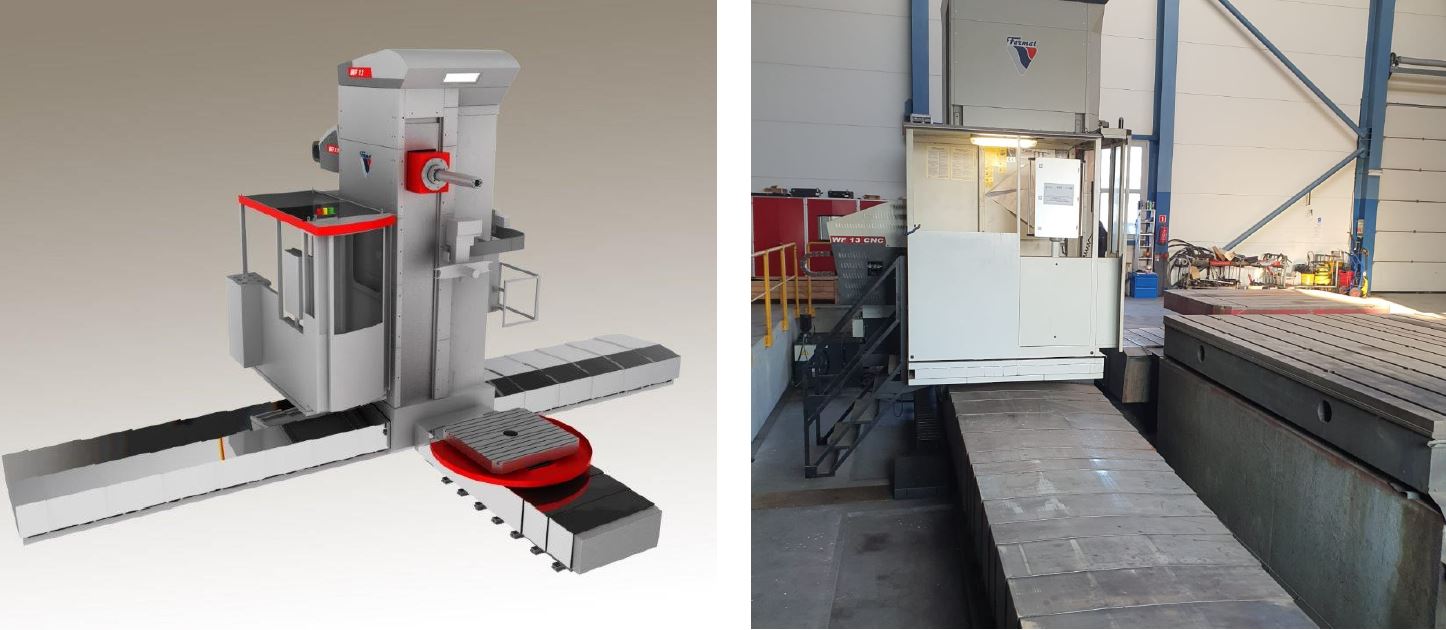

Due to the dynamic development of our company, we have decided

Decision to expand our machine park by a large part

FERMAT WF 13 CNC milling and drilling machine.

The following are the most important parameters of the machine:

- Weight of the machined parts up to 15 tons

- Round table dimensions 2000 x 2400

- Longitudinal movement of the stand – X 5 800 mm.

- Vertical movement of the headstock – Y 2 500 mm

- Stroke of the slide – Z 600 mm

- Spindle extension – H 730 mm

- completely CNC-controlled. HEIDENHAIN iTNC 530

control

- 4 linear axes

- extendable work spindle

- sliding 600 mm slide

- Tool cooling via spindle axis

- Diameter of the work spindle ø130 mm

- Spindle speed 10 – 3,000 rpm

- max. spindle torque 2008 Nm

- Slide dimensions 400 x 400 mm

- Main engine power 37 kW

- Working feed rate in all axes 1 – 8,000 mm / min

The ERMAK SPEED BEND PRO 4.220 hydraulic press from ERMAK is an extremely versatile, efficient and precisely controlled CNC machine, which provides great flexibility in terms of bending length.

The DELEM DA CNC graphic control system allows convenient operation via a color touch screen. The solid construction of the machine combined with a precise CNC control system ensures long-lasting and reliable operation. The machine is easily controlled via an LCD touch screen mounted on the left pivot arm.

The CNC control of the press brake automatically adjusts the pressure force. Bending tolerance, punch setting, bending force and tool safety zones are calculated automatically.

Basic parameters:

- pressure – 220 T

- bending length – 4100 mm

- distance between columns – 3600 mm

- DELEM DA 66T CNC control/

- 15″ high resolution TFT color touch screen

- machine dimensions 5.15 m x 2.25 m x 3.0 m

- machine weight approx. 13,900 kg